Occasionally you may experience some problems while printing objects. If you experience any of the following issues, it may be necessary to adjust the printer’s z-axis offset.

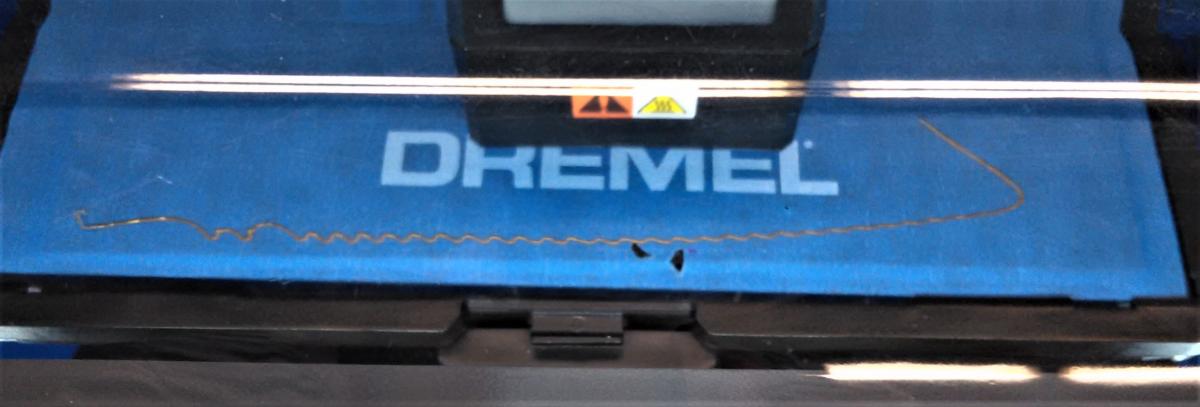

- The filament does not stick to the build plate during printing (see figures 1 and 2).

- Completed objects are extremely difficult to remove from the build plate.

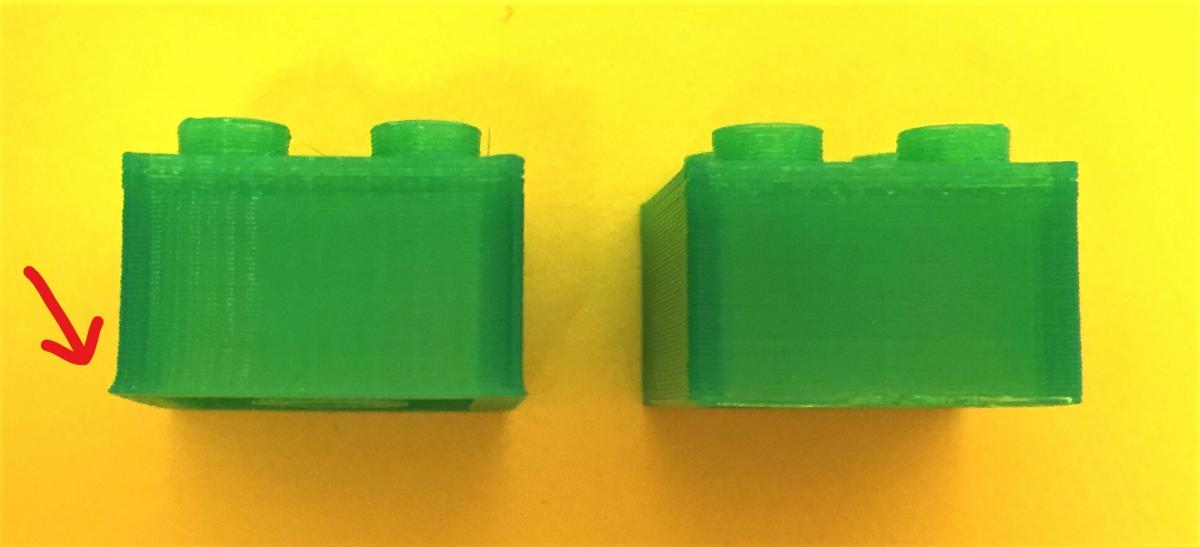

- Objects with straight edges are bowed outwards on the bottom (see figure 3).

Figure 1: The test strip appears a a wavy line rather than a straight line, indicating that the extruder was too far from the build plate.

Figure 2: In the image on the left, the lefthand object did not adhere to the building plate during printing, resulting in misplaced filament. In the image on the right, the lefthand object did not adhere to the build plate, resulting in the filament balling up. In both cases, the extruder was too far from the build plate.

Figure 3: The walls of the object on the left bow outward, indicating that the extruder was too close to the build plate during printing.

If you are experiencing any of the problems described above, first ensure that the build plate is level.

If the build plate is level and the problem persists, contact NORWELD staff for guidance on raising/lowering the printer's z-axis offset.